When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

Thank you!

If you do not wish to have your item(s) delivered on data disc(s), I can provide them on a flash drive and other means as well. Just let me know if a disc does not work for you and we can discuss delivery by other methods.

COMBINING SHIPPING COSTS

Are you purchasing multiple items? I will: a) combine all invoices before payment and charge shipping equivalent to one item, or b) refund all shipping costs in excess of one item after payment.

All derivative (i.e. change in media; by compilation) work from this underlying U.S. Government public domain/public release data is COPYRIGHT © GOVPUBS

$3.00 first class shipping in U.S.

Includes the Adobe Acrobat Reader for reading and printing publications.

Numerous illustrations and matrices.

Contains the following key public domain (not copyrighted) U.S. Government publication(s) on one CD-ROM in both Microsoft PowerPoint and Adobe Acrobat PDF file formats:

TITLE: Road Construction I, II and III, 140 slides

SLIDE TOPICS, SUBTOPICS and CONTENTS:

Road Construction I: General Concepts

Quality Assurance Representative Training

May 2007

Outline

Typical pavement cross-sections

Drainage

Retaining walls

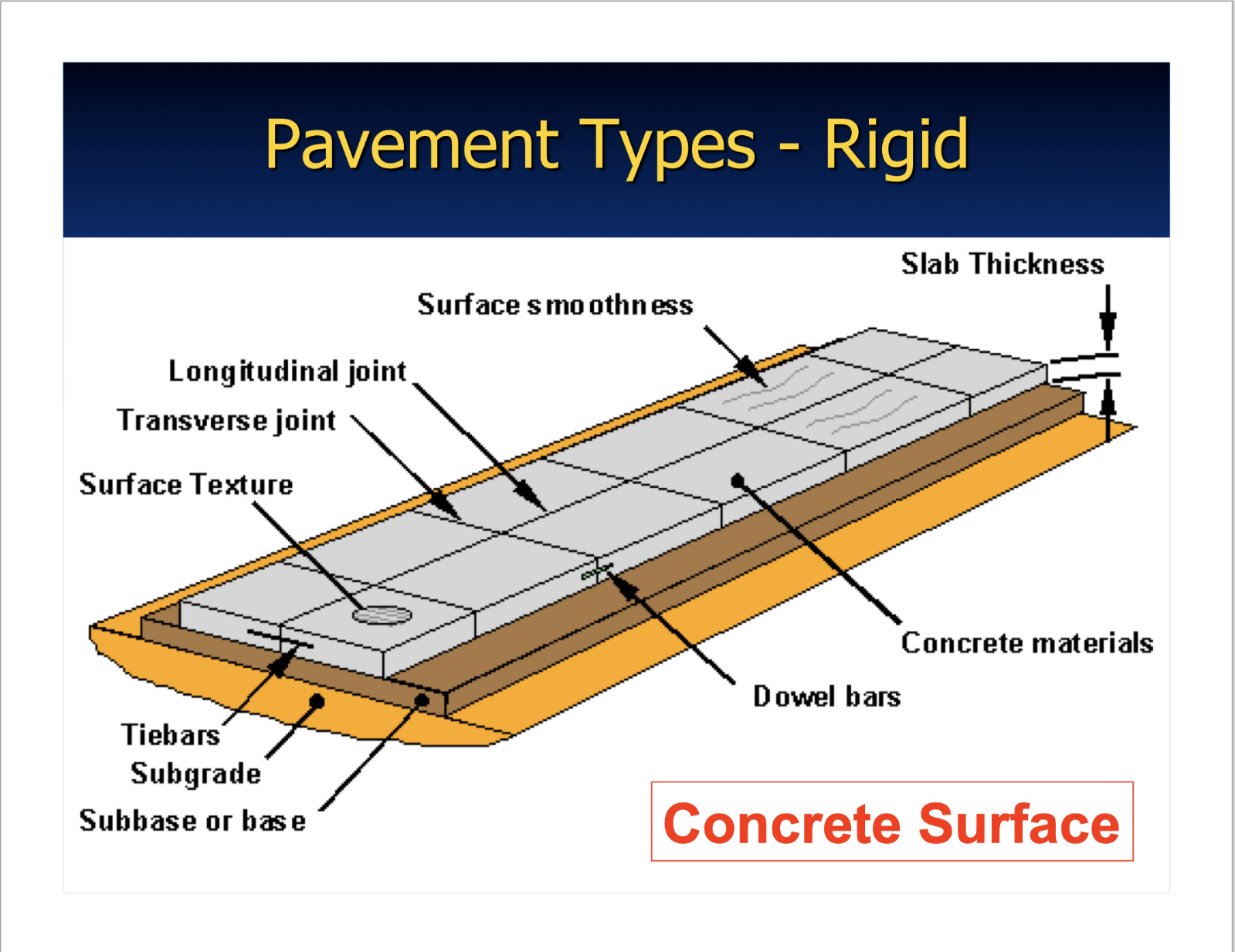

Asphalt concrete – mixture designPavement Types - Rigid

Pavement Types - Flexible

Pavement Types - Flexible

Pavement Types - Flexible

Asphalt Pavements - Terms

Subgrade - the foundation of the pavement that may be:

Natural, in-place material

Compacted fill

Section 02300

Asphalt Pavements - Terms

Subbase course - provides:

load distribution to the subgrade

frost protection

economy

Section 02721

Asphalt Pavements - Terms

Base course - a layer directly beneath the surface course to

distribute loads

provide drainage and provide frost protection

Section 02722

Asphalt Pavements - Terms

Surface course - a structural surface designed to resist the effects of

tire pressures

weather

abrasion

Section 02741

Asphalt Pavement Types

Typical Cross Section

Measuring Crown Slope

Typical Cross Section

Stone Culvert

Stone Culvert

Stone Culvert

Stone Culvert

Concrete Culvert

Pipe Installation in Trench

Soils – Ease of Compaction

Compaction in Small Areas

Flowable Fill (Controlled Low-Strength Material)

Pipe Installation on Embankment

Headwall for 600 & 800 mm Walls

Retaining Walls

Retaining Walls

Retaining Walls

Retaining Walls

Why drainage is so important

Retaining Walls

Drainage

Shaping Ditches

Drainage

Stone Work

Drainage

Curb and Gutters

Drainage

Durability of Curbs

Soil Compaction Equipment

Variables influencing effectiveness

Gross weight

Drum or tires or “feet”

Vibratory versus static

Speed

Number of passes

Soil Compaction Equipment

Smooth drum

Vibratory most effective

Static for sealing

Soil Compaction Equipment

“Footed” Rollers

Kneading action

Compacting from bottom to top (walking out)

Soil Compaction Equipment

Rubber-tired roller

Effective for most soils (but not highly plastic soils)

Finds weak spots!

Tire pressure is important

Effectiveness of Roller Types

Don’t Compact in Snow

Asphalt Mixture Design

“Job mix formula”

50-blow versus 75-blow

Aggregate information

Binder type (penetration)

Asphalt cement

bitumen

Percent binder

Asphalt Mixture Design

Penetration Grading

60-70 is common

Asphalt Mixture Design

Asphalt Mixture Design

Asphalt Mixture Design

Discussion

Road Construction II: Materials

Quality Assurance Representative Training

May 2007

Aggregates and Soil

Particle sizes and distributions

Crushing

Aggregate properties

Relative density (Proctor)

Liquid and plastic limits

Unified Soil Classification System

Portland cement concrete – mixture proportioning

Particle Sizes

Boulder – average dimension >= 305 mm

Cobble – average dimension = 76 to 305 mm

Coarse Aggregate (gravel) – retained No. 4 sieve (4.76 mm)

Fine Aggregate – retained No. 200 sieve (0.075 mm)

Silt and clay – passing No. 200 sieve (0.075 mm)

U.S. Department of Agriculture: clay < 0.002 mm

Particle Size Distributions

Aggregate Crushing

Aggregate Production

Aggregate Production

Sieving

Sieve Numbers

Aggregate Gradation

Aggregate Gradation

Aggregate Soundness

Five cycles (typical) of wetting and drying

Calculate % loss

Applicable to various sieve sizes

LA Abrasion

500 revolutions (typical)

Sieve over No. 12 (1.70-mm) sieve

Calculate % loss

Flat and Elongated Particles

Laboratory Compaction

Modified Proctor (typically 152 mm diameter)

5 layers, 56 blows each

4.54 kg rammer

457 mm drop

Volume = 2125 cm3

Energy = 2,700 kN-m/m3

Moisture-Density Curve

Field Density

Unified Soil Classification System

Adapted from the Airfield Classification System

Grouping is based on engineering properties

Relies on two basic properties:

Gradation for < 75 mm

Plasticity of minus No. 40 fraction

Unified Soil Classification System

Fine-Grained Soil

USCS – fine-grained soil

USCS – coarse-grained soil

Coarse fraction: > #200

USCS – coarse-grained soil

USCS – coarse-grained soil

Portland Cement Concrete

Portland Cement – ASTM C 150

Type I = ordinary

Type III = high-early strength

Type V = high sulfate resistance

Portland Cement Concrete

Compositional requirements

Ask for mill test certificate

Physical requirements

Good for quick checks on variable cement sources

Portland Cement Concrete

Design strength (f’c) versus

Required target strength (f’cr) for supplier

Portland Cement Concrete

rock : sand : cement

~ 3 : 2 : 1 (by volume)

Portland Cement Concrete

Accurate Mix Design

Absolute material volumes

ACI 211.1

Trial batches

Slump

Air

Temperature

Unit weight

Strength

Portland Cement Concrete

Strength is highly dependent on w/c ratio:Water = “mixing water”

Excludes water absorbed by aggregate

Includes free water on aggregate surfaces

Portland Cement Concrete

Coarse Aggregate

Largest control

Drying Cement Concrete

Mortar fraction

Sand, cement, and water

Must coat coarse particles

Shrinks as it gains strength

Provides lubrication

Must be air-entrained for freeze-thaw environment

Concrete Batch Plant

Concrete Batch Plant

Concrete Batch Plant

Concrete Batch Plant

Concrete Batch Plant

Concrete Batch Plant

Concrete Batch Plant

Surface moisture on aggregates contributes to water/cement ratio

Accounting for Aggregate Moisture

Moisture probes for aggregate near point of batching concrete

Temporary

Speedy or microwaveConcrete DeliveryDiscussion

Road Construction III: Asphalt and Surface and tack coats

Placement of asphalt concrete

Asphalt plantsAsphalt Concrete Pavements

Preparatory Meeting Discussion Issues

Equipment

Laydown Machine Control Testing

Timing

Number of Tests

Responsible Parties

Reporting

Test Section

Binders

Asphalt Cement (Bitumen)

Viscosity Grade: AC-20

Penetration Grade: 60-70

Emulsions – asphalt dispersed in water with help from an emulsifying agent (surface-active)

Cutbacks – asphalt made fluid by petroleum solvent (naphtha or kerosene)

No diesel!

Prime and Tack Coats

Prime on base (may or may not be required)

Tack on asphalt surface

Purpose is to bind pavement layers

Prime Coat

Emulsion

Cutback

Type depends on base porosity and air temperature

Rate of application = 0.7 to 1.8 liter/m2

Residual asphalt

Tack Coat

Emulsion

Cutback

Heated asphalt cement (bitumen)

High penetration grade to keep temperature requirement low

Rate of application = 0.2 to 0.7 liters/m2

Residual asphalt

Prime and Tack Coats

Important to have:

prepared surface,

proper application rate, and

sufficient cure time (24 to 48 hours)

Reduce amount of construction traffic on tacked surface as much as possible

Clean before placing HMA on top

Tack Coat

Tack Coat

Tack Coat

Tack Coat

HMA Laydown Operations

HMA Laydown Operations

Symptoms of Problems with Hot-Mix Asphalt

Blue Smoke

Stiff Appearance

Some Aggregates Not Coated with AC

Shiny, Wet Appearance

Liquid Asphalt Dripping from Haul Truck

Dull Brown Color

Steam

Segregation

HMA Laydown Operations

Common Temperatures

AC storage – 150 to 175 C

Aggregate – 145 to 160 C

Mixing – 130 to 165 C

Compaction – 85 to 165 C

Begin rolling at hottest temperature at which the mix will support the roller without moving horizontally (i.e. cracking).

Check Cracking

Purposes of Compaction

To prevent further densification under traffic (rutting)

To provide shear strength

To ensure mixture is waterproof

To prevent excessive oxidation of asphalt binder

3 Stages of Stages of Rolling

HMA Compaction

HMA Compaction

HMA Compaction

HMA Compaction

HMA Joints

HMA Joints

HMA Joints

HMA Joints

HMA Joints

HMA Joints – Weak Link

Hand Work

Smoothness

Field Density

Satisfactory HMA Paving

Proper Mix Design

Surface Preparation

Satisfactory Laydown Techniques

Sufficient Rollers and Satisfactory Rolling Techniques

Satisfactory Mixture Thickness

Satisfactory Joint Construction Techniques

Specification Section

Asphalt Plants

Batch plant

Drum Mix plant

Batch Plant

Batch Plant

Two places where aggregate gradation is controlled

Batch Plant

Batch Plant

Second place to control gradation

Batch Plant

Batch Plant

Drum Mix Plant

Drum Mix Plant

Calibrating Cold Feed

Calibrating Cold Feed

Discussion